Rare Earth Laminated Samarium Cobalt Permanent Magnets for High Speed Motors

Laminated permanent magnets are specially designed magnetic components that are made by cutting a whole magnet into many smaller magnets, which are then glued together with a specific glue, and which are insulated from each other to minimize electromagnetic eddy currents. For example, rare earth magnets are glued to each other or to a steel plate, with the entire stack having the same polarity.

Brand:

KINGS MAGNETOrder(MOQ):

10Payment:

T/T 100% IN ADVANCE (negotiable)Product Origin:

Xiamen,CNShipping Port:

XIAMEN

What are laminated magnets?

What are laminated magnets?

Laminated permanent magnets are specially designed magnetic components that are made by cutting a whole magnet into many smaller magnets, which are then glued together with a specific glue, and which are insulated from each other to minimize electromagnetic eddy currents. For example, rare earth magnets are glued to each other or to a steel plate, with the entire stack having the same polarity.

Characteristics of laminated magnets

Characteristics of laminated magnets

1. Good surface magnetic consistency;

2. The unique production method increases the competitive advantages of production efficiency, manufacturing precision and cost control;

3. The magnet adopts integral plating surface protection technology, which has excellent resistance to high temperature, humidity and corrosion;

4. Insulating these small magnets from each other by means of insulating stitching;

5. The thickness of the insulating layer is within 0.04mm;

6. The bonding strength of the insulating layer at room temperature can reach more than 50Mpa;

7. Maximum working temperature up to 200°C;

8. The geometric tolerance of laminated magnets is within ±05mm;

9. They are available in samarium cobalt and neodymium iron boron materials;

10. Customized sizes and shapes are also acceptable.

Why choose laminated magnets?

Why choose laminated magnets?

Laminated magnets reduce eddy current losses in high efficiency motors. High efficiency requires the best materials, and Arnold L-Type laminated magnets have been proven to reduce eddy current losses in high-efficiency motors. Less eddy current loss means less heat and less waste.

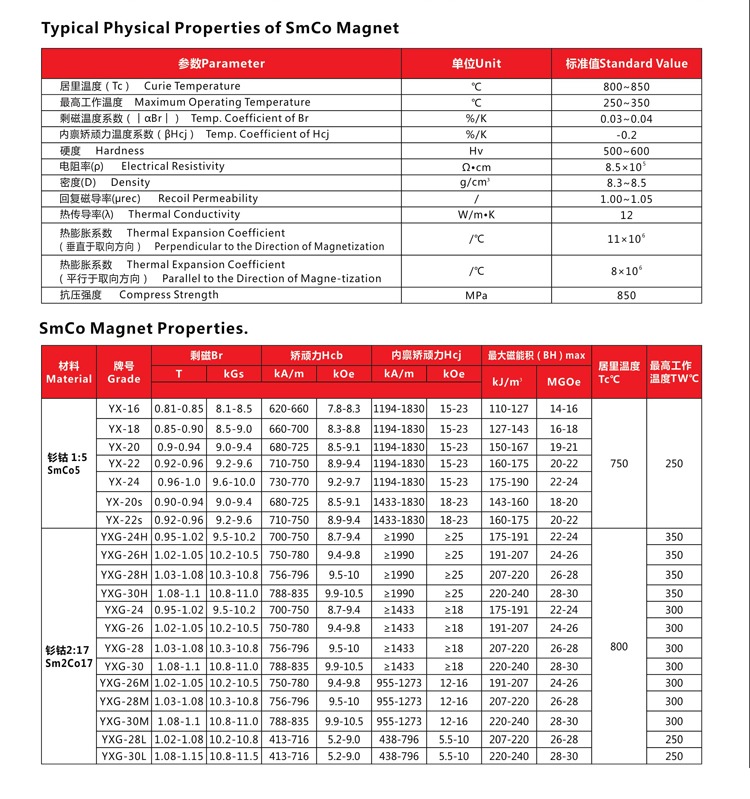

Samarium Cobalt Magnet Performance Table

Key Applications for Laminated Magnets:

The aerospace, automotive, motorsports and industrial markets are now turning to laminated rare-earth magnets in an effort to balance the trade-off between power and heat.

Question 1: What are the benefits of using laminated magnets?

A: Laminated magnets reduce eddy current losses, increase flux density, improve thermal stability and reduce magnet size.

Question 2: How are laminated magnets made?

A: Laminated magnets are made by stacking thin layers of magnetic material with insulating layers and then bonding them together using processes such as hot pressing or epoxy bonding.

Question 3: What are laminated magnets used for?

A: Laminated magnets are used in applications such as electric motors, generators, transformers and magnetic sensors.

Question 4: What types of magnetic materials are used to make laminated magnets?

A: Laminated magnets can be made from a variety of magnetic materials, including neodymium-iron-boron (NdFeB), samarium-cobalt (SmCo), and ferrite.

Question 5: What are the key design considerations for laminated magnets?

A: Design considerations for laminated magnets include the thickness and number of magnetic and insulating layers, as well as the bonding process used.

Q6: Are laminated magnets environmentally friendly?

A: Laminated magnets are generally considered to be more environmentally friendly than solid magnets because they require less magnetic material and produce less waste during the manufacturing process.