By dividing the magnet into thin layers, the eddy currents are confined to smaller volumes, reducing their impact on the overall magnetic performance.

Brand:

KINGS MAGNETItem NO.:

MTLMPayment:

100%/70% INADVANCEProduct Origin:

ChinaShipping Port:

Shanghai,Ningbo,XiamenColor:

BlackLead Time:

22-30daysIntroduction of Laminated Magnet

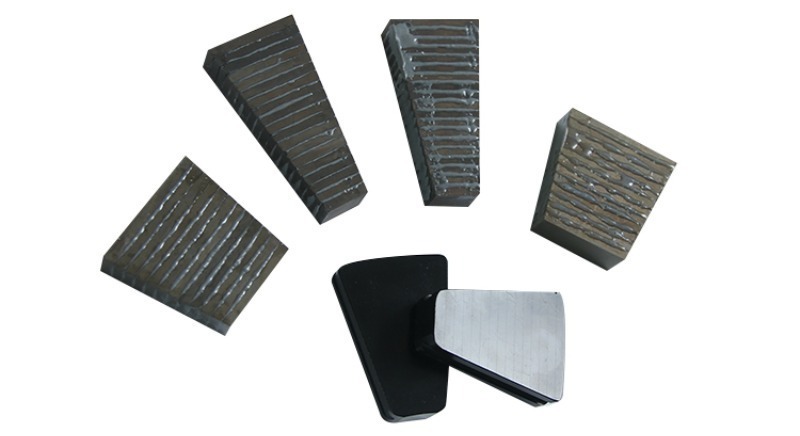

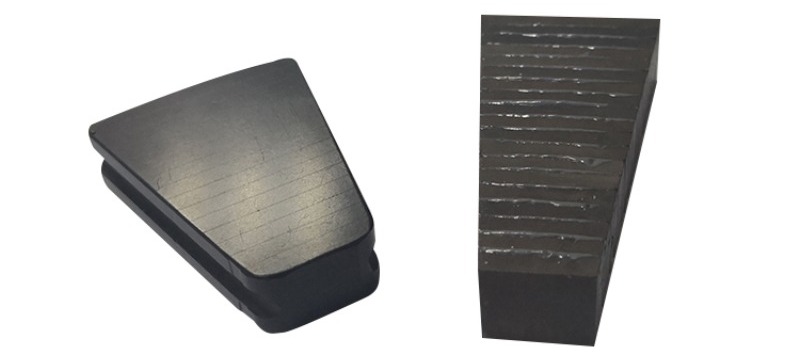

Laminated magnets, also known as segmented magnets, consist of two or more individual magnets that are bonded and insulated to each other. They were developed to enhance the performance of electric machines by preventing the magnets from overheating. Laminated NdFeB magnets are commonly used for this purpose, but SmCo 2:17 also serves as a fundamental magnetic material for magnet segmentation technology.

KINGS MAGNET minimizes the tradeoff by offering best-in-class materials with

1.The thinnest available insulating layers, <20 um

2.Performance at temperatures up to 200˚C

3.Magnet layers from .5 mm and up in custom shapes and sizes in SmCo Magnet and NdFeB Magnet

Application of laminated magnets

Laminated magnets are often used in electric motors, generators, transformers, and other electromagnetic devices where controlling energy losses is essential.

Characteristics of Laminated magnets

How Magnet Segmentation Conquers Demagnetization?

Magnet segmentation, or dividing a magnet into distinct segments or pieces, is a strategy employed to address demagnetization and enhance the overall performance and stability of magnetic systems. Here's how magnet segmentation conquers demagnetization:

In summary, magnet segmentation is a technique that provides a level of control over the magnetic field, minimizing the impact of demagnetization and enhancing the stability and reliability of magnetic systems, particularly in applications where demagnetization is a critical concern.

Essential Manufacturing Process of Laminated Magnets

First, NdFeB blanks are sliced into equal-thickness single pieces and then laminated with insulation glue. The fully laminated blank is then cut, sliced, and ground to the desired geometry and size, creating a complete laminated NdFeB magnet. The bonding adhesive typically achieves a maximum insulation rate of 95%. However, due to the adhesive, electroplating is not possible, as the magnet body is no longer electrically conductive. As an alternative, common coating solutions include epoxy-painting (usually black) or phosphorization.

Custom magnet steps

The above are the general steps for customizing magnets. If you have special requirements, please send an email with special instructions.

Certification

All the magnets we offer comply with international standards such as ISO9001. We have strict requirements for quality and raw materials. We can provide material safety certificate, ROSH, REACH certificate, factory inspection certificate, etc.

FAQ

Q: How about our after-sale service?

A: We have 24-hours online contact ways, you can leave us message when you are available, or write all the questions in an email, we promise everyone question will get our response in 24 hours.

Q: How to pay?

A: T/T in advance(telegraphic transfer-bank order), for small order, or samples order, or shipment by air.

Paypal – for small order or samples order.

Q: If I have more questions, where can I get the answer?

A: Any questions, please feel free to contact us any time.