D5*30mm, Ni coated neodymium rod magnet.

Item NO.:

KINGS MAGNETOrder(MOQ):

10Payment:

100% in advanceProduct Origin:

ChinaShipping Port:

Xiamen/Ningbo/ShanghaiColor:

Ni Coating/CustomLead Time:

28-35 daysProduct Description

These are D5*30mm, rod bar shape neodymium magnet. The garde and coating can be customized.

Hot-selling grade: N35, N40, N52.

1.Grade of NdFeB magnet

|

Grade |

BrmT(KG) |

bHc KA/m(KOe) |

iHc KA/m(KOe) |

(BH)maxKJ/m3 (MGOe) |

Tw.℃ |

|

N35 |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥955(≥12) |

263-287(33-36) |

80℃ |

|

N38 |

1220-1250(12.2_12.5) |

≥899( ≥11.3) |

≥955 ( ≥12) |

287-310(36-39) |

80℃ |

|

N40 |

1250-1280 (12.5-12.8) |

≥907 ( ≥11.4) |

≥955 ( ≥12) |

302-326(38-41) |

80℃ |

|

N42 |

1280-1320(12.8-13.2) |

≥915( ≥11.5) |

≥955 ( ≥12) |

318-342(40-43) |

80℃ |

|

N45 |

1320-1380(13.2-13.8) |

≥923 ( ≥11.6) |

≥955 ( ≥12) |

342-366(43-46) |

80℃ |

|

N48 |

1380-1420(13.8-14.2) |

≥923( ≥11.6) |

≥955 ( ≥12) |

366-390(46-49) |

80℃ |

|

N50 |

1400-1450(14.0-14.5) |

≥796( ≥10.0) |

≥876( ≥11) |

382-406(48-51) |

60℃ |

|

N52 |

1430-1480(14.3-14.8) |

≥796( ≥10.0) |

≥876 ( ≥11) |

398-422(50-53) |

60℃ |

|

35M |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥1114 ( ≥14) |

263-287(33-36) |

100℃ |

|

38M |

1220-1250(12.2-12.5) |

≥899( ≥11.3) |

≥1114(≥14) |

287-310(36-39) |

100℃ |

|

40M |

1250-1280(12.5-12.8) |

≥923( ≥11.6) |

≥1114 ( ≥14) |

302-326(38-40) |

100℃ |

|

42M |

1280-1320(12.8-13.2) |

≥955(≥12.0) |

≥1114( ≥14) |

318-342(40-43) |

100℃ |

|

45M |

1320-1380(13.2-13.8) |

≥955 ( ≥12.5) |

≥1114( ≥14) |

342-366(43-46) |

100℃ |

|

48M |

1360-1430(13.6-14.3) |

≥1027( ≥12.9) |

≥1114 ( ≥14) |

366-390(46-49) |

100℃ |

|

50M |

1400-1450(14.0-14.5) |

≥1033 ( ≥13.0) |

≥1114 ( ≥14) |

382-406(48-51) |

100℃ |

|

35H |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥1353 ( ≥17) |

263-287(33-36) |

120℃ |

|

38H |

1220-1250(12.2-12.5) |

≥899( ≥11.3) |

≥1353 ( ≥17) |

287-310(36-39) |

120℃ |

|

40H |

1250-1280(12.5-12.8) |

≥923 ( ≥11.6) |

≥1353 ( ≥17) |

302-326(38-41) |

120℃ |

|

42H |

1280-1320(12.8-13.2) |

≥955 ( ≥12.0) |

≥1353 ( ≥17) |

318-342(40-43) |

120℃ |

|

45H |

1300-1360(13.0-13.6) |

≥963 ( ≥12.1) |

≥1353 ( ≥17) |

326-358(43-46) |

120℃ |

|

48H |

1370-1430(13.7-14.3) |

≥955 ( ≥12.5) |

≥1353 ( ≥17) |

366-390(46-49) |

120℃ |

|

30SH |

1080-1130(10.8-11.3) |

≥804 ( ≥10.1) |

≥1592 ( ≥20) |

233-247(28-31) |

150℃ |

|

33SH |

1130-1170(11.3-11.7) |

≥844( ≥10.6) |

≥1592 ( ≥20) |

247-271(31-34) |

150℃ |

|

35SH |

1170-1220(11.7-12.2) |

≥876( ≥11.0) |

≥1592 ( ≥20) |

263-287(33-36) |

150℃ |

|

38SH |

1220-1250(12.2-12.5) |

≥907(≥11.4) |

≥1592 ( ≥20) |

287-310(36-39) |

150℃ |

|

40SH |

1240-1280(12.5-12.8) |

≥939( ≥11.8) |

≥1592 ( ≥20) |

302-326(38-41) |

150℃ |

|

42SH |

1280-1320(12.8-13.2) |

≥987(≥12.4) |

≥1592 ( ≥20) |

318-342(40-43) |

150℃ |

|

45SH |

1320-1380(13.2-13.8) |

≥1003 ( ≥12.6) |

≥1592 ( ≥20) |

342-366(43-46) |

150℃ |

|

30UH |

1080-1130(10.8-11.3) |

≥812 ( ≥10.2) |

≥1990 ( ≥25) |

223-247(28-31) |

180℃ |

|

33UH |

1130-1170(11.3-11.7) |

≥852( ≥10.7) |

≥1990 ( ≥25) |

247-271(31-34) |

180℃ |

|

35UH |

1180-1220(11.8-12.2) |

≥860 ( ≥10.8) |

≥1990 ( ≥25) |

263-287(33-36) |

180℃ |

|

38UH |

1220-1250(12.2-12.5) |

≥876 ( ≥11.0) |

≥1990 ( ≥25) |

287-310(36-39) |

180℃ |

|

40UH |

1240-1280(12.4-12.8) |

≥899 ( ≥11.3) |

≥1990 ( ≥25) |

302-326(38-41) |

180℃ |

|

28EH |

1040-1090(10.4-10.9) |

≥780 ( ≥9.8) |

≥2388 ( ≥30) |

207-231(26-29) |

200℃ |

|

30EH |

1080-1130(10.8-11.3) |

≥812( ≥10.2) |

≥2388( ≥30) |

223-247(28-31) |

200℃ |

|

33EH |

1130-1170(11.3-11.7) |

≥836( ≥10.5) |

≥2388 ( ≥30) |

247-271(31-34) |

200℃ |

|

35EH |

1170-1220(11.7-12.2) |

≥876( ≥11.0) |

≥2388 ( ≥30) |

263-287(33-36) |

200℃ |

|

38EH |

1220-1250(12.2-12.5) |

≥899 ( ≥11.3) |

≥2388( ≥30) |

287-310(36-39) |

200℃ |

|

40EH |

1240-1280(12.4-12.8) |

≥939(≥11.6) |

≥2388 ( ≥30) |

302-326(38-41) |

200℃ |

|

30AH |

1080-1120(10.8-11.2) |

≥804( ≥10.1) |

≥2786( ≥35) |

223-239(28-30) |

220℃ |

|

33AH |

1140-1170(11.4-11.7) |

≥844( ≥10.6) |

≥2786 ( ≥35) |

247-263(31-33) |

220℃ |

|

35AH |

1170-1210(11.7-12.1) |

≥876( ≥10.9) |

≥2786( ≥35) |

263-279(33-35) |

220℃ |

2.Pull force reference

| Size | Grade | Pull Force |

| D8*30mm |

N35 | At least 27 LBS |

| N38 | At least 28 LBS | |

| N40 | At least 29 LBS | |

| N42 | At least 31 LBS | |

| N48 | At least 36 LBS | |

| N52 | At least 40 LBS |

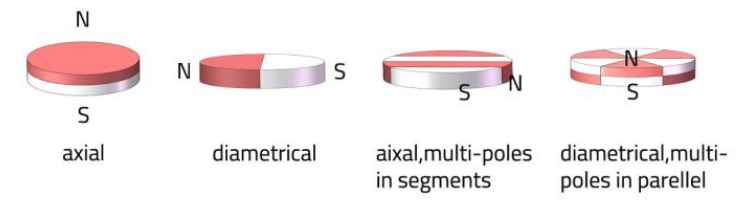

3.Direction of magnetization of rod Ndfeb magnet

4.Coating

5.Technological process of production of rod NdFeb magnet

6.The display of Ni coated rod neodymium magnet

7.Certificate

8.Packing & Delivery

9.FAQ

1. Who are we?

We are based in Fujian, China, start from 2014, sell to North America(20.00%), Oceania(15.00%), Western Europe(15.00%), Eastern Asia(10.00%), Southern Europe(10.00%), Northern Europe(10.00%), Eastern Europe(10.00%), South Asia(5.00%), Southeast Asia(3.00%), Mid East(2.00%).

2. How can we guarantee quality?

Always a pre-production sample before mass production.

Always final Inspection before shipment.

3. What can you buy from us?

Neodymium Magnet / Bonded Neodymium Magnet / Pot Magnet / Rubber Coated Magnet / Magnetic Welding Holder / Alnico Magnet.

4. Why choose us?

* Rich Business Experience

* Excellent Service Spirit

* Fast Shipping Channel

* Abundant Material Resources

* High-quality Product

* Competitive Price

5. What services can we provide?

*Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDU,Express Delivery;

*Accepted Payment Currency:USD,EUR,CNY;

*Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union;

*Language Spoken:English,Chinese