Custom Hot Sale Circular N35 Neodymium Monster Magnet 26×12 mm Magnets

Ndfeb High performance magnetic materials, we can manufacture a variety of sizes to meet your needs

Brand:

KINGS MAGNETOrder(MOQ):

20Payment:

100%in advanceProduct Origin:

ChinaShipping Port:

Xiamen/Ningbo/ShanghaiColor:

Galvanized, gold-plated, nickel-plated,Black epoxyLead Time:

25-35daysNeodymium magnets are the strongest permanent magnets available. It is easily formed in a variety of shapes and sizes and is one of the most widely used magnetic materials. We are a magnet manufacturer that supports customization of various sizes.

Grade of NdfeB Magnet

You can choose the desired performance according to your actual application, follow up the operating temperature

|

Grade |

Remanence BrmT(KG) |

Coercivity HCB KA/m(KOe) |

Intrinsic Coercivity HCJ KA/m(KOe) |

(BH)maxKJ/m3 (MGOe) |

Tw.℃ |

|

N35 |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥955(≥12) |

263-287(33-36) |

80℃ |

|

N38 |

1220-1250(12.2_12.5) |

≥899( ≥11.3) |

≥955 ( ≥12) |

287-310(36-39) |

80℃ |

|

N40 |

1250-1280 (12.5-12.8) |

≥907 ( ≥11.4) |

≥955 ( ≥12) |

302-326(38-41) |

80℃ |

|

N42 |

1280-1320(12.8-13.2) |

≥915( ≥11.5) |

≥955 ( ≥12) |

318-342(40-43) |

80℃ |

|

N45 |

1320-1380(13.2-13.8) |

≥923 ( ≥11.6) |

≥955 ( ≥12) |

342-366(43-46) |

80℃ |

|

N48 |

1380-1420(13.8-14.2) |

≥923( ≥11.6) |

≥955 ( ≥12) |

366-390(46-49) |

80℃ |

|

N50 |

1400-1450(14.0-14.5) |

≥796( ≥10.0) |

≥876( ≥11) |

382-406(48-51) |

60℃ |

|

N52 |

1430-1480(14.3-14.8) |

≥796( ≥10.0) |

≥876 ( ≥11) |

398-422(50-53) |

60℃ |

|

35M |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥1114 ( ≥14) |

263-287(33-36) |

100℃ |

|

38M |

1220-1250(12.2-12.5) |

≥899( ≥11.3) |

≥1114(≥14) |

287-310(36-39) |

100℃ |

|

40M |

1250-1280(12.5-12.8) |

≥923( ≥11.6) |

≥1114 ( ≥14) |

302-326(38-40) |

100℃ |

|

42M |

1280-1320(12.8-13.2) |

≥955(≥12.0) |

≥1114( ≥14) |

318-342(40-43) |

100℃ |

|

45M |

1320-1380(13.2-13.8) |

≥955 ( ≥12.5) |

≥1114( ≥14) |

342-366(43-46) |

100℃ |

|

48M |

1360-1430(13.6-14.3) |

≥1027( ≥12.9) |

≥1114 ( ≥14) |

366-390(46-49) |

100℃ |

|

50M |

1400-1450(14.0-14.5) |

≥1033 ( ≥13.0) |

≥1114 ( ≥14) |

382-406(48-51) |

100℃ |

|

35H |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥1353 ( ≥17) |

263-287(33-36) |

120℃ |

|

38H |

1220-1250(12.2-12.5) |

≥899( ≥11.3) |

≥1353 ( ≥17) |

287-310(36-39) |

120℃ |

|

40H |

1250-1280(12.5-12.8) |

≥923 ( ≥11.6) |

≥1353 ( ≥17) |

302-326(38-41) |

120℃ |

|

42H |

1280-1320(12.8-13.2) |

≥955 ( ≥12.0) |

≥1353 ( ≥17) |

318-342(40-43) |

120℃ |

|

45H |

1300-1360(13.0-13.6) |

≥963 ( ≥12.1) |

≥1353 ( ≥17) |

326-358(43-46) |

120℃ |

|

48H |

1370-1430(13.7-14.3) |

≥955 ( ≥12.5) |

≥1353 ( ≥17) |

366-390(46-49) |

120℃ |

|

30SH |

1080-1130(10.8-11.3) |

≥804 ( ≥10.1) |

≥1592 ( ≥20) |

233-247(28-31) |

150℃ |

|

33SH |

1130-1170(11.3-11.7) |

≥844( ≥10.6) |

≥1592 ( ≥20) |

247-271(31-34) |

150℃ |

|

35SH |

1170-1220(11.7-12.2) |

≥876( ≥11.0) |

≥1592 ( ≥20) |

263-287(33-36) |

150℃ |

|

38SH |

1220-1250(12.2-12.5) |

≥907(≥11.4) |

≥1592 ( ≥20) |

287-310(36-39) |

150℃ |

|

40SH |

1240-1280(12.5-12.8) |

≥939( ≥11.8) |

≥1592 ( ≥20) |

302-326(38-41) |

150℃ |

|

42SH |

1280-1320(12.8-13.2) |

≥987(≥12.4) |

≥1592 ( ≥20) |

318-342(40-43) |

150℃ |

|

45SH |

1320-1380(13.2-13.8) |

≥1003 ( ≥12.6) |

≥1592 ( ≥20) |

342-366(43-46) |

150℃ |

|

30UH |

1080-1130(10.8-11.3) |

≥812 ( ≥10.2) |

≥1990 ( ≥25) |

223-247(28-31) |

180℃ |

|

33UH |

1130-1170(11.3-11.7) |

≥852( ≥10.7) |

≥1990 ( ≥25) |

247-271(31-34) |

180℃ |

|

35UH |

1180-1220(11.8-12.2) |

≥860 ( ≥10.8) |

≥1990 ( ≥25) |

263-287(33-36) |

180℃ |

|

38UH |

1220-1250(12.2-12.5) |

≥876 ( ≥11.0) |

≥1990 ( ≥25) |

287-310(36-39) |

180℃ |

|

40UH |

1240-1280(12.4-12.8) |

≥899 ( ≥11.3) |

≥1990 ( ≥25) |

302-326(38-41) |

180℃ |

|

28EH |

1040-1090(10.4-10.9) |

≥780 ( ≥9.8) |

≥2388 ( ≥30) |

207-231(26-29) |

200℃ |

|

30EH |

1080-1130(10.8-11.3) |

≥812( ≥10.2) |

≥2388( ≥30) |

223-247(28-31) |

200℃ |

|

33EH |

1130-1170(11.3-11.7) |

≥836( ≥10.5) |

≥2388 ( ≥30) |

247-271(31-34) |

200℃ |

|

35EH |

1170-1220(11.7-12.2) |

≥876( ≥11.0) |

≥2388 ( ≥30) |

263-287(33-36) |

200℃ |

|

38EH |

1220-1250(12.2-12.5) |

≥899 ( ≥11.3) |

≥2388( ≥30) |

287-310(36-39) |

200℃ |

|

40EH |

1240-1280(12.4-12.8) |

≥939(≥11.6) |

≥2388 ( ≥30) |

302-326(38-41) |

200℃ |

|

30AH |

1080-1120(10.8-11.2) |

≥804( ≥10.1) |

≥2786( ≥35) |

223-239(28-30) |

220℃ |

|

33AH |

1140-1170(11.4-11.7) |

≥844( ≥10.6) |

≥2786 ( ≥35) |

247-263(31-33) |

220℃ |

|

35AH |

1170-1210(11.7-12.1) |

≥876( ≥10.9) |

≥2786( ≥35) |

263-279(33-35) |

220℃ |

Coating

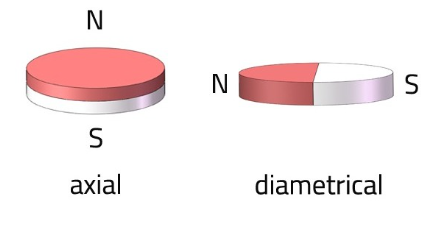

Magnetization Direction

Disc NdFeB magnet can be magnetized in two main ways, it depends on your application requirements.

Application

1. Daily necessities: bags, suitcases, clothing, cups, ect;

2. Electronic products: computer, keyboard, display, LED ect;

3. Home: locks, tables, chairs, cabinets, beds, Windows,ect;

4. Mechanical equipment and automation: motor, drone, elevator, security monitoring, dishwasher,ect;

Certification

All the magnets we offer comply with international standards such as ISO9001. We have strict requirements for quality and raw materials. We can provide material safety certificate, ROSH, REACH certificate, factory inspection certificate, etc.

The advantages of Ndfeb magnets:

1. High magnetic properties

2. High cost performance

3. Strong machinability, can be made through mechanical processing to meet the purpose of the shape

FAQ

Q: How about our after-sale service?

A: We have 24-hours online contact ways, you can leave us message when you are available, or write all the questions in an email, we promise everyone question will get our response in 24 hours.

Q: How to pay?

A: T/T in advance(telegraphic transfer-bank order), for small order, or samples order, or shipment by air.

Paypal – for small order or samples order.

Q: I would like some samples for testing, do you have samples in stock?

A: For regular size, we may have samples, such as D5X3mm original magnet. For customized size magnets, we don't have stock, if you want to produce, you need to charge sample fee.