Rubber Coated Neodymium Magnetic Materials Cylinder Round Ring Magnets

The rubber coated magnet is to cover the outer surface of the magnet with a layer of glue, which can avoid damage

Brand:

KINGS MAGNETOrder(MOQ):

10Payment:

100%in advanceProduct Origin:

ChinaShipping Port:

Xiamen/ShanghaiColor:

silverLead Time:

25-35daysProduct Description

Rubber coated magnets, also known as weatherproof magnets, are made by Neodymium magnet, stainless steel and durable rubber coating.

The protective rubber coating protects magnets from chipping, liquid, and corrosion. Thus can be regarded as an ideal solution for both indoor and outdoor holding applications which need high magnetic strength.

Grade of NdFeB magnet

|

Grade |

BrmT(KG) |

bHc KA/m(KOe) |

iHc KA/m(KOe) |

(BH)maxKJ/m3 (MGOe) |

Tw.℃ |

|

N35 |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥955(≥12) |

263-287(33-36) |

80℃ |

|

N38 |

1220-1250(12.2_12.5) |

≥899( ≥11.3) |

≥955 ( ≥12) |

287-310(36-39) |

80℃ |

|

N40 |

1250-1280 (12.5-12.8) |

≥907 ( ≥11.4) |

≥955 ( ≥12) |

302-326(38-41) |

80℃ |

|

N42 |

1280-1320(12.8-13.2) |

≥915( ≥11.5) |

≥955 ( ≥12) |

318-342(40-43) |

80℃ |

|

N45 |

1320-1380(13.2-13.8) |

≥923 ( ≥11.6) |

≥955 ( ≥12) |

342-366(43-46) |

80℃ |

|

N48 |

1380-1420(13.8-14.2) |

≥923( ≥11.6) |

≥955 ( ≥12) |

366-390(46-49) |

80℃ |

|

N50 |

1400-1450(14.0-14.5) |

≥796( ≥10.0) |

≥876( ≥11) |

382-406(48-51) |

60℃ |

|

N52 |

1430-1480(14.3-14.8) |

≥796( ≥10.0) |

≥876 ( ≥11) |

398-422(50-53) |

60℃ |

|

35M |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥1114 ( ≥14) |

263-287(33-36) |

100℃ |

|

38M |

1220-1250(12.2-12.5) |

≥899( ≥11.3) |

≥1114(≥14) |

287-310(36-39) |

100℃ |

|

40M |

1250-1280(12.5-12.8) |

≥923( ≥11.6) |

≥1114 ( ≥14) |

302-326(38-40) |

100℃ |

|

42M |

1280-1320(12.8-13.2) |

≥955(≥12.0) |

≥1114( ≥14) |

318-342(40-43) |

100℃ |

|

45M |

1320-1380(13.2-13.8) |

≥955 ( ≥12.5) |

≥1114( ≥14) |

342-366(43-46) |

100℃ |

|

48M |

1360-1430(13.6-14.3) |

≥1027( ≥12.9) |

≥1114 ( ≥14) |

366-390(46-49) |

100℃ |

|

50M |

1400-1450(14.0-14.5) |

≥1033 ( ≥13.0) |

≥1114 ( ≥14) |

382-406(48-51) |

100℃ |

|

35H |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥1353 ( ≥17) |

263-287(33-36) |

120℃ |

|

38H |

1220-1250(12.2-12.5) |

≥899( ≥11.3) |

≥1353 ( ≥17) |

287-310(36-39) |

120℃ |

|

40H |

1250-1280(12.5-12.8) |

≥923 ( ≥11.6) |

≥1353 ( ≥17) |

302-326(38-41) |

120℃ |

|

42H |

1280-1320(12.8-13.2) |

≥955 ( ≥12.0) |

≥1353 ( ≥17) |

318-342(40-43) |

120℃ |

|

45H |

1300-1360(13.0-13.6) |

≥963 ( ≥12.1) |

≥1353 ( ≥17) |

326-358(43-46) |

120℃ |

|

48H |

1370-1430(13.7-14.3) |

≥955 ( ≥12.5) |

≥1353 ( ≥17) |

366-390(46-49) |

120℃ |

|

30SH |

1080-1130(10.8-11.3) |

≥804 ( ≥10.1) |

≥1592 ( ≥20) |

233-247(28-31) |

150℃ |

|

33SH |

1130-1170(11.3-11.7) |

≥844( ≥10.6) |

≥1592 ( ≥20) |

247-271(31-34) |

150℃ |

|

35SH |

1170-1220(11.7-12.2) |

≥876( ≥11.0) |

≥1592 ( ≥20) |

263-287(33-36) |

150℃ |

|

38SH |

1220-1250(12.2-12.5) |

≥907(≥11.4) |

≥1592 ( ≥20) |

287-310(36-39) |

150℃ |

|

40SH |

1240-1280(12.5-12.8) |

≥939( ≥11.8) |

≥1592 ( ≥20) |

302-326(38-41) |

150℃ |

|

42SH |

1280-1320(12.8-13.2) |

≥987(≥12.4) |

≥1592 ( ≥20) |

318-342(40-43) |

150℃ |

|

45SH |

1320-1380(13.2-13.8) |

≥1003 ( ≥12.6) |

≥1592 ( ≥20) |

342-366(43-46) |

150℃ |

|

30UH |

1080-1130(10.8-11.3) |

≥812 ( ≥10.2) |

≥1990 ( ≥25) |

223-247(28-31) |

180℃ |

|

33UH |

1130-1170(11.3-11.7) |

≥852( ≥10.7) |

≥1990 ( ≥25) |

247-271(31-34) |

180℃ |

|

35UH |

1180-1220(11.8-12.2) |

≥860 ( ≥10.8) |

≥1990 ( ≥25) |

263-287(33-36) |

180℃ |

|

38UH |

1220-1250(12.2-12.5) |

≥876 ( ≥11.0) |

≥1990 ( ≥25) |

287-310(36-39) |

180℃ |

|

40UH |

1240-1280(12.4-12.8) |

≥899 ( ≥11.3) |

≥1990 ( ≥25) |

302-326(38-41) |

180℃ |

|

28EH |

1040-1090(10.4-10.9) |

≥780 ( ≥9.8) |

≥2388 ( ≥30) |

207-231(26-29) |

200℃ |

|

30EH |

1080-1130(10.8-11.3) |

≥812( ≥10.2) |

≥2388( ≥30) |

223-247(28-31) |

200℃ |

|

33EH |

1130-1170(11.3-11.7) |

≥836( ≥10.5) |

≥2388 ( ≥30) |

247-271(31-34) |

200℃ |

|

35EH |

1170-1220(11.7-12.2) |

≥876( ≥11.0) |

≥2388 ( ≥30) |

263-287(33-36) |

200℃ |

|

38EH |

1220-1250(12.2-12.5) |

≥899 ( ≥11.3) |

≥2388( ≥30) |

287-310(36-39) |

200℃ |

|

40EH |

1240-1280(12.4-12.8) |

≥939(≥11.6) |

≥2388 ( ≥30) |

302-326(38-41) |

200℃ |

|

30AH |

1080-1120(10.8-11.2) |

≥804( ≥10.1) |

≥2786( ≥35) |

223-239(28-30) |

220℃ |

|

33AH |

1140-1170(11.4-11.7) |

≥844( ≥10.6) |

≥2786 ( ≥35) |

247-263(31-33) |

220℃ |

|

35AH |

1170-1210(11.7-12.1) |

≥876( ≥10.9) |

≥2786( ≥35) |

263-279(33-35) |

220℃ |

You can select the appropriate parameters according to the table and the specific application or experience

Size:The range of sizes we can produce(We support customization of various sizes)

Block neodymium magnet:

|

Length(mm) |

Width(mm) |

Thickness(mm) |

Tolerance(mm) |

Direction of Magnetzation |

|

L 1-240 |

W 1-100 |

T 1-80 |

+/-0.05 - +/-0.1 |

Through Length,Width or Thickness |

Round neodymium magnet:

|

Diameter(mm) |

Height (mm) |

Tolerance(mm) |

Direction of Magnetzation |

|

∮0.5-240 |

H 0.5-80 |

+/-0.05 - +/-0.1 |

Axial Magnetized |

|

∮0.5-60 |

H 0.5-40 |

+/-0.05 - +/-0.1 |

Diametrical Magnetized |

Ring neodymium magnet:

|

Outer Diameter(mm) |

Inner Daimeter(mm) |

Hight (mm) |

Tolerance or Wall Thickness (mm) |

Direction of Magnetzation |

|

3 ≦ OD ≦ 240 |

1 ≦ ID ≦ 200 |

1 ≦ H ≦ 80 |

+/-0.05 - +/-0.1 |

Axial Magnetized |

|

3 ≦ OD ≦ 90 |

1 ≦ ID ≦ 70 |

1 ≦ H ≦ 80 |

+/-0.05 - +/-0.1 |

Diametrical Magnetized |

|

20 ≦ OD ≦ 75 |

15 ≦ ID ≦ 68 |

5 ≦ H ≦ 50 |

2 ≦ T ≦ 7 |

Radial Magnetized |

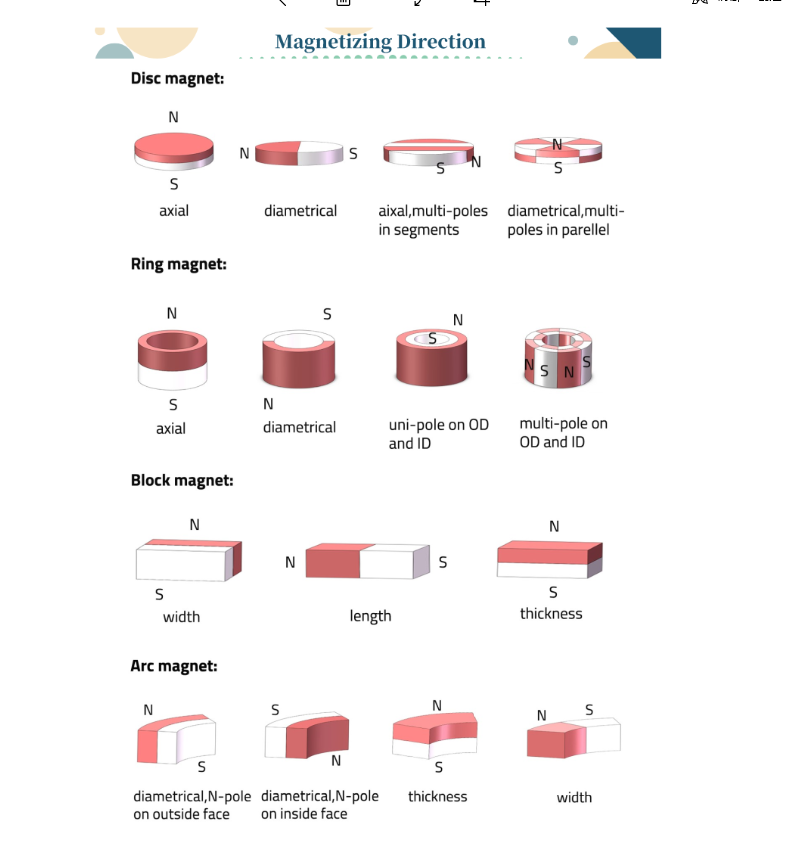

Direction of magnetization of Ndfeb magnet

Coating:

Rubber coating we support a minimum of 0.8mm

Magnet coating:

Technological process of production of Sintered NdFeb magnet

Certificate

Packing & Delivery

FAQ

How can we guarantee quality?

Always a pre-production sample before mass production.

Always final Inspection before shipment.

What can you buy from us?

Neodymium Magnet / Bonded Neodymium Magnet / Pot Magnet / Rubber Coated Magnet / Magnetic Welding Holder / Alnico Magnet.

What services can we provide?

*Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDU,Express Delivery;

*Accepted Payment Currency:USD,EUR,CNY;

*Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union;

*Language Spoken:English,Chinese

If you have any other questions, please feel free to contact us by email

Email: Tanya@Kingsmagent.com