Permanent Custom Shape N35 N52 Neodymium Magnet Bar For Motor Sensor

Customized Zinc coated neodymium magnet bar, grade, coating optional. Welcome to bring your drawings to consult your custom magnet needs.

Item NO.:

KINGS MAGNETOrder(MOQ):

1000Payment:

100% in advanceProduct Origin:

ChinaShipping Port:

Xiamen/Ningbo/ShanghaiColor:

Zinc Coating/CustomLead Time:

28-35 daysProduct Description

Ndfeb magnets are the strongest rare earth magnets on the market and come in a variety of shapes, sizes and grades. It has a wide range of applications and can be used in industry and our daily lives.

Because it easily reacts with oxygen and is easily corroded. Therefore, NdFeB magnets must be coated. You can choose different coatings according to different usage requirements.

We accept customized magnets of any reasonable size and shape. You are welcome to consult us with drawings.

1.Grade of NdFeB magnet

|

Grade |

BrmT(KG) |

bHc KA/m(KOe) |

iHc KA/m(KOe) |

(BH)maxKJ/m3 (MGOe) |

Tw.℃ |

|

N35 |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥955(≥12) |

263-287(33-36) |

80℃ |

|

N38 |

1220-1250(12.2_12.5) |

≥899( ≥11.3) |

≥955 ( ≥12) |

287-310(36-39) |

80℃ |

|

N40 |

1250-1280 (12.5-12.8) |

≥907 ( ≥11.4) |

≥955 ( ≥12) |

302-326(38-41) |

80℃ |

|

N42 |

1280-1320(12.8-13.2) |

≥915( ≥11.5) |

≥955 ( ≥12) |

318-342(40-43) |

80℃ |

|

N45 |

1320-1380(13.2-13.8) |

≥923 ( ≥11.6) |

≥955 ( ≥12) |

342-366(43-46) |

80℃ |

|

N48 |

1380-1420(13.8-14.2) |

≥923( ≥11.6) |

≥955 ( ≥12) |

366-390(46-49) |

80℃ |

|

N50 |

1400-1450(14.0-14.5) |

≥796( ≥10.0) |

≥876( ≥11) |

382-406(48-51) |

60℃ |

|

N52 |

1430-1480(14.3-14.8) |

≥796( ≥10.0) |

≥876 ( ≥11) |

398-422(50-53) |

60℃ |

|

35M |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥1114 ( ≥14) |

263-287(33-36) |

100℃ |

|

38M |

1220-1250(12.2-12.5) |

≥899( ≥11.3) |

≥1114(≥14) |

287-310(36-39) |

100℃ |

|

40M |

1250-1280(12.5-12.8) |

≥923( ≥11.6) |

≥1114 ( ≥14) |

302-326(38-40) |

100℃ |

|

42M |

1280-1320(12.8-13.2) |

≥955(≥12.0) |

≥1114( ≥14) |

318-342(40-43) |

100℃ |

|

45M |

1320-1380(13.2-13.8) |

≥955 ( ≥12.5) |

≥1114( ≥14) |

342-366(43-46) |

100℃ |

|

48M |

1360-1430(13.6-14.3) |

≥1027( ≥12.9) |

≥1114 ( ≥14) |

366-390(46-49) |

100℃ |

|

50M |

1400-1450(14.0-14.5) |

≥1033 ( ≥13.0) |

≥1114 ( ≥14) |

382-406(48-51) |

100℃ |

|

35H |

1170-1220(11.7-12.2) |

≥868( ≥10.9) |

≥1353 ( ≥17) |

263-287(33-36) |

120℃ |

|

38H |

1220-1250(12.2-12.5) |

≥899( ≥11.3) |

≥1353 ( ≥17) |

287-310(36-39) |

120℃ |

|

40H |

1250-1280(12.5-12.8) |

≥923 ( ≥11.6) |

≥1353 ( ≥17) |

302-326(38-41) |

120℃ |

|

42H |

1280-1320(12.8-13.2) |

≥955 ( ≥12.0) |

≥1353 ( ≥17) |

318-342(40-43) |

120℃ |

|

45H |

1300-1360(13.0-13.6) |

≥963 ( ≥12.1) |

≥1353 ( ≥17) |

326-358(43-46) |

120℃ |

|

48H |

1370-1430(13.7-14.3) |

≥955 ( ≥12.5) |

≥1353 ( ≥17) |

366-390(46-49) |

120℃ |

|

30SH |

1080-1130(10.8-11.3) |

≥804 ( ≥10.1) |

≥1592 ( ≥20) |

233-247(28-31) |

150℃ |

|

33SH |

1130-1170(11.3-11.7) |

≥844( ≥10.6) |

≥1592 ( ≥20) |

247-271(31-34) |

150℃ |

|

35SH |

1170-1220(11.7-12.2) |

≥876( ≥11.0) |

≥1592 ( ≥20) |

263-287(33-36) |

150℃ |

|

38SH |

1220-1250(12.2-12.5) |

≥907(≥11.4) |

≥1592 ( ≥20) |

287-310(36-39) |

150℃ |

|

40SH |

1240-1280(12.5-12.8) |

≥939( ≥11.8) |

≥1592 ( ≥20) |

302-326(38-41) |

150℃ |

|

42SH |

1280-1320(12.8-13.2) |

≥987(≥12.4) |

≥1592 ( ≥20) |

318-342(40-43) |

150℃ |

|

45SH |

1320-1380(13.2-13.8) |

≥1003 ( ≥12.6) |

≥1592 ( ≥20) |

342-366(43-46) |

150℃ |

|

30UH |

1080-1130(10.8-11.3) |

≥812 ( ≥10.2) |

≥1990 ( ≥25) |

223-247(28-31) |

180℃ |

|

33UH |

1130-1170(11.3-11.7) |

≥852( ≥10.7) |

≥1990 ( ≥25) |

247-271(31-34) |

180℃ |

|

35UH |

1180-1220(11.8-12.2) |

≥860 ( ≥10.8) |

≥1990 ( ≥25) |

263-287(33-36) |

180℃ |

|

38UH |

1220-1250(12.2-12.5) |

≥876 ( ≥11.0) |

≥1990 ( ≥25) |

287-310(36-39) |

180℃ |

|

40UH |

1240-1280(12.4-12.8) |

≥899 ( ≥11.3) |

≥1990 ( ≥25) |

302-326(38-41) |

180℃ |

|

28EH |

1040-1090(10.4-10.9) |

≥780 ( ≥9.8) |

≥2388 ( ≥30) |

207-231(26-29) |

200℃ |

|

30EH |

1080-1130(10.8-11.3) |

≥812( ≥10.2) |

≥2388( ≥30) |

223-247(28-31) |

200℃ |

|

33EH |

1130-1170(11.3-11.7) |

≥836( ≥10.5) |

≥2388 ( ≥30) |

247-271(31-34) |

200℃ |

|

35EH |

1170-1220(11.7-12.2) |

≥876( ≥11.0) |

≥2388 ( ≥30) |

263-287(33-36) |

200℃ |

|

38EH |

1220-1250(12.2-12.5) |

≥899 ( ≥11.3) |

≥2388( ≥30) |

287-310(36-39) |

200℃ |

|

40EH |

1240-1280(12.4-12.8) |

≥939(≥11.6) |

≥2388 ( ≥30) |

302-326(38-41) |

200℃ |

|

30AH |

1080-1120(10.8-11.2) |

≥804( ≥10.1) |

≥2786( ≥35) |

223-239(28-30) |

220℃ |

|

33AH |

1140-1170(11.4-11.7) |

≥844( ≥10.6) |

≥2786 ( ≥35) |

247-263(31-33) |

220℃ |

|

35AH |

1170-1210(11.7-12.1) |

≥876( ≥10.9) |

≥2786( ≥35) |

263-279(33-35) |

220℃ |

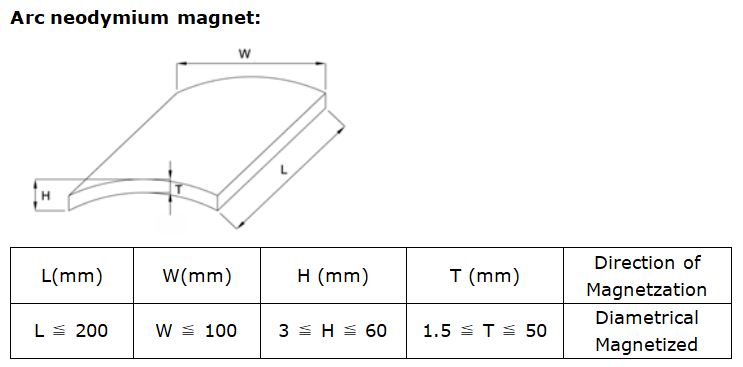

2.Size(The range of sizes we can produce)

3.Coating

4.Technological process of production of Sintered NdFeb magnet

5.The display of custom zinc coated neodymium magnet

6.Certificate

7.Packing & Delivery

8.FAQ

1. Who are we?

We are based in Fujian, China, start from 2014, sell to North America(20.00%), Oceania(15.00%), Western Europe(15.00%), Eastern Asia(10.00%), Southern Europe(10.00%), Northern Europe(10.00%), Eastern Europe(10.00%), South Asia(5.00%), Southeast Asia(3.00%), Mid East(2.00%).

2. How can we guarantee quality?

Always a pre-production sample before mass production.

Always final Inspection before shipment.

3. What can you buy from us?

Neodymium Magnet / Bonded Neodymium Magnet / Pot Magnet / Rubber Coated Magnet / Magnetic Welding Holder / Alnico Magnet.

4. Why choose us?

* Rich Business Experience

* Excellent Service Spirit

* Fast Shipping Channel

* Abundant Material Resources

* High-quality Product

* Competitive Price

5. What services can we provide?

*Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDU,Express Delivery;

*Accepted Payment Currency:USD,EUR,CNY;

*Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union;

*Language Spoken:English,Chinese