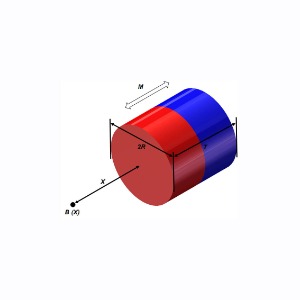

LNG60 D40X20mm Round Resistant Alnico Magnet Axial Magnetization

Alnico magnets LNG60 grade have good stability and are often used for precision instruments or aerospace ,servo motor,applications.

Brand:

KINGS MAGNETItem NO.:

LNG60-40X20NAOrder(MOQ):

10Payment:

T/T 100% IN ADVANCEProduct Origin:

Xiamen,CNShipping Port:

XIAMENColor:

silver grayProduct Information:

| Product Name | Alnico Magnets |

| Material | Alnico Magnets |

| Demension | Customized |

| Shape | Disk, Block, Ball, Ring, Cylinder etc. or customized |

| Magnetization Direction | Thickness, Length, Axially, Diametre, Radially, Multipolar |

| Application | Experimental Teaching |

| Packaging | Cystosepiment, Carton Box |

| Delivery Time | 45-60 days |

| Gared | Br(Gs) | Hcj(Oe) |

BH(max) MGOe |

g/cm³ |

%Change Per ℃ | Tw(℃) |

| LNG60(Alnico 5-7 ) | 13500 | 740 | 7.5 | 7.3 | Near Br -0.02 | 525 |

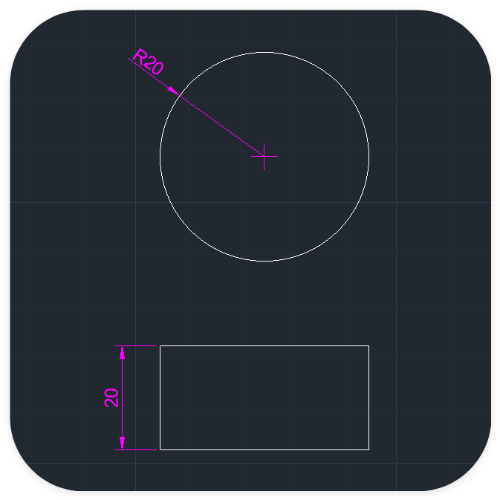

Drawings:

Other performance parameters:

Other properties are subject to customization.

|

MaterialCode

|

Remanence

|

Coercivity

|

Intrinsic

Coercivity |

Max.Energy

Prouct

|

Density

|

% ChangePer c

|

Tc

|

Remark

|

||||

|

Br

|

Hcb

|

Hcj

|

(BH)max

|

D

|

||||||||

|

mT

|

Gs

|

KA/m

|

Oe

|

KA/m

|

Oe

|

KJ/m3

|

MGOe

|

g/cm3

|

%K

|

℃

|

||

|

FLN8

|

520

|

5200

|

40

|

500

|

43

|

540

|

8-10

|

1.0-1.25

|

6.8

|

-0.022

|

760

|

Isotropic

|

|

FLNG12

|

700

|

7000

|

40

|

500

|

43

|

540

|

12-14

|

1.5-1.75

|

7.0

|

-0.014

|

810

|

|

|

FLNGT14

|

570

|

5700

|

76

|

950

|

78

|

980

|

14-16

|

1.75-2.0

|

7.1

|

-0.02

|

850

|

|

|

FLNGT18

|

560

|

5600

|

88

|

1100

|

90

|

1130

|

18-22

|

2.25-2.75

|

7.2

|

-0.02

|

850

|

|

|

FLNG28

|

1050

|

10500

|

46

|

580

|

47

|

590

|

28-33

|

3.5-4.15

|

7.2

|

-0.016

|

850

|

Anisotropic

|

|

FLNG34

|

1100

|

11000

|

50

|

630

|

51

|

640

|

34-38

|

4.3-4.8

|

7.2

|

-0.016

|

890

|

|

|

FLNGT28

|

1000

|

10000

|

56

|

700

|

57

|

710

|

28-30

|

3.5-3.8

|

7.2

|

-0.020

|

850

|

|

|

FLNGT31

|

780

|

7800

|

104

|

1300

|

106

|

1130

|

33-36

|

3.9-4.5

|

7.2

|

-0.020

|

850

|

|

|

FLNG33J

|

650

|

6500

|

136

|

1700

|

150

|

1880

|

31-36

|

4.15-4.5

|

7.2

|

-0.020

|

850

|

|

|

FLNGT38

|

800

|

8000

|

123

|

1550

|

126

|

1580

|

38-42

|

4.75-5.3

|

7.2

|

-0.020

|

850

|

|

|

FLNGT42

|

880

|

8800

|

120

|

1500

|

122

|

1530

|

42-48

|

5.3-6.0

|

7.25

|

-0.020

|

850

|

|

|

Material

Code

|

Remanence

|

Intrinsic

Coercivity

|

Max.Energy

Prouct

(BH)max

|

Density

D

|

Equivalent

MMPA

Class

|

% Change

Per c

|

Tc

|

Tw

|

||||

|

Br

|

Hcj

|

|||||||||||

|

mT

|

Gs

|

KA/m

|

Oe

|

KJ/m3

|

MGOe

|

g/cm3

|

Near Br

|

Near Hcj

|

℃

|

℃

|

||

|

*LN9

|

680

|

6800

|

30

|

380

|

9.0

|

1.13

|

6.9

|

Alnico3

|

-0.03

|

-0.02

|

810

|

450

|

|

*LN10

|

600

|

6000

|

40

|

500

|

10.0

|

1.20

|

6.9

|

-0.03

|

-0.02

|

810

|

450

|

|

|

*LNG12

|

720

|

7200

|

45

|

500

|

12.4

|

1.55

|

7.0

|

Alnico2

|

-0.03

|

-0.02

|

810

|

450

|

|

*LNG13

|

700

|

7000

|

48

|

600

|

12.8

|

1.60

|

7.0

|

|||||

|

LNG37

|

1200

|

13000

|

48

|

600

|

37.0

|

4.65

|

7.3

|

Alnico5

|

-0.02

|

0.02

|

860

|

525

|

|

LNG40

|

1250

|

12500

|

48

|

600

|

40.0

|

5.00

|

7.3

|

|||||

|

LNG44

|

1250

|

12500

|

52

|

650

|

44.0

|

5.50

|

7.3

|

|||||

|

LNG52

|

1300

|

13000

|

56

|

700

|

52.0

|

6.50

|

7.3

|

Alnico5DG

|

||||

|

LNG60

|

1350

|

13500

|

59

|

740

|

60.0

|

7.50

|

7.3

|

Alnico5-7

|

||||

|

LNGT28

|

1000

|

10000

|

58

|

720

|

28.0

|

3.50

|

7.3

|

Alnico6

|

-0.02

|

0.03

|

860

|

525

|

|

LNGT36J

|

700

|

7000

|

140

|

1750

|

36.0

|

4.50

|

7.3

|

Alnico8HC

|

-0.025

|

0.02

|

860

|

550

|

|

*LNGT18

|

580

|

5800

|

100

|

1250

|

18.0

|

2.20

|

7.3

|

Alnico8

|

-0.025

|

0.02

|

860

|

550

|

|

LNGT32

|

800

|

8000

|

100

|

1250

|

32.0

|

4.00

|

7.3

|

Alnico8

|

-0.025

|

0.02

|

860

|

550

|

|

LNGT40

|

800

|

8000

|

110

|

1380

|

40.0

|

5.00

|

7.3

|

|||||

|

LNGT60

|

900

|

9000

|

110

|

1380

|

60.0

|

7.50

|

7.3

|

Alnico9

|

-0.025

|

0.02

|

860

|

550

|

|

LNGT72

|

1050

|

10500

|

112

|

1400

|

72.0

|

9.00

|

7.3

|

|||||

Applications:

Alnico magnets LNG60 grade can reach a maximum operating temperature of 525°C and do not require a coating because of its corrosion and oxidation resistance; it is a more economical choice than NdFeB.

Customize other shapes:

Customized Alnico magnets with more shapes are supported, but customers are required to provide design drawings.

Special shapes cannot be predicted in terms of gauss and tensile force and need to be tested after completion of production.