Injection molded ferrite is a magnet formed by injection molding process after mixing ferrite magnetic powder and resin (PA6/PA12/PA66/PPS)

Brand:

KINGS MAGNETItem NO.:

MFPayment:

100%/70%INVOICEProduct Origin:

ChinaShipping Port:

Xiamen/Ningbo/ShanghaiColor:

BlackLead Time:

25-30 daysProduct Information:

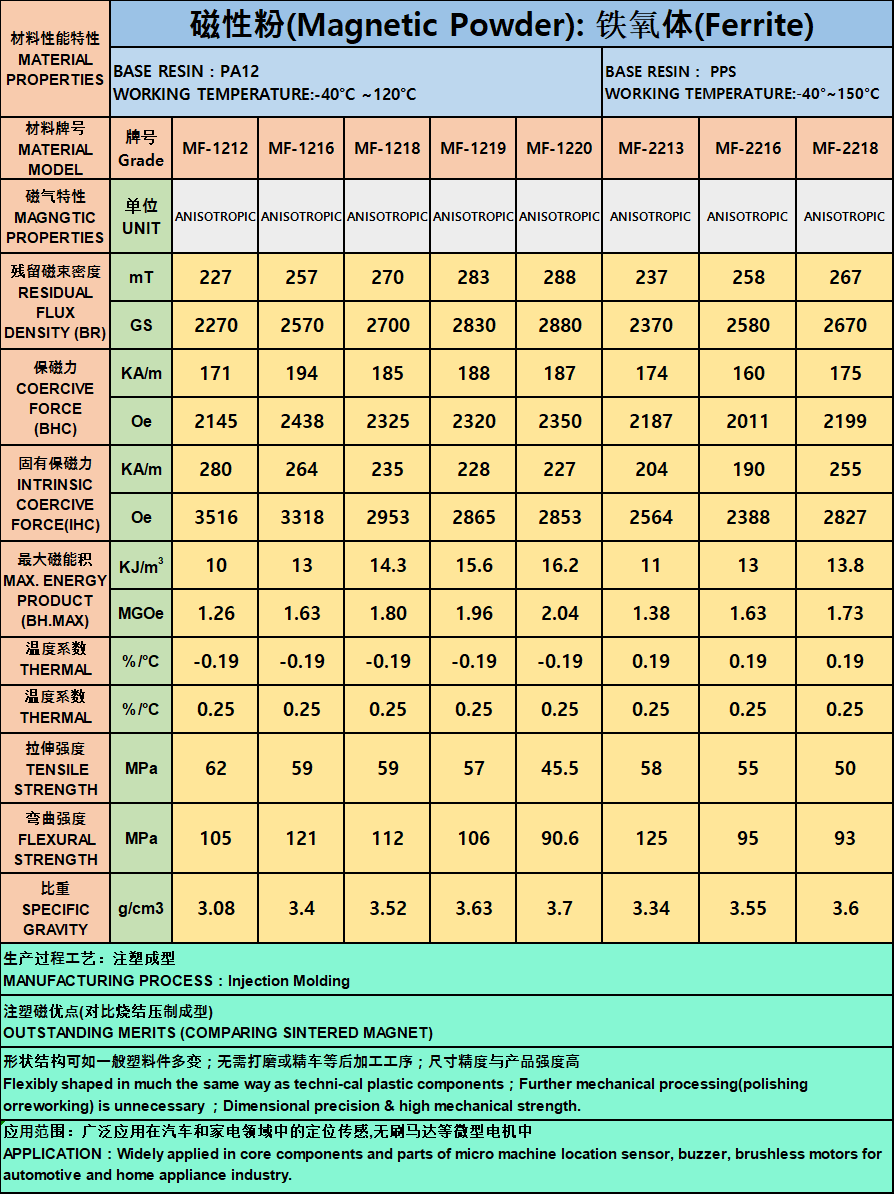

Injection ferrite magnet is a type of bonded magnet manufactured by mixing ferrite magnetic powder with the thermoplastic binder which then enables the magnet to be injection molded just like any other plastic would be. The maximum operating temperature of PA12 based, PA6 based, and PPS based magnet can achieve 120, 150, and 180 degrees Celsius, respectively. Injection ferrite magnet also has excellent mechanical strength, dimensional accuracy, shape applicability, and integrated ability with other functional parts, which totally same as injection molded Neodymium magnet. Its magnetic performance and cost is significantly lower than injection molded Neodymium magnet and widely served for sensors and low performance motors. Anisotropic injection ferrite magnet need to apply a permanent magnetic field or an electromagnetic field to align molten compound during the injection molding process.

Properties of injection molded ferrite:

Direction of magnetization of Ndfeb magnet

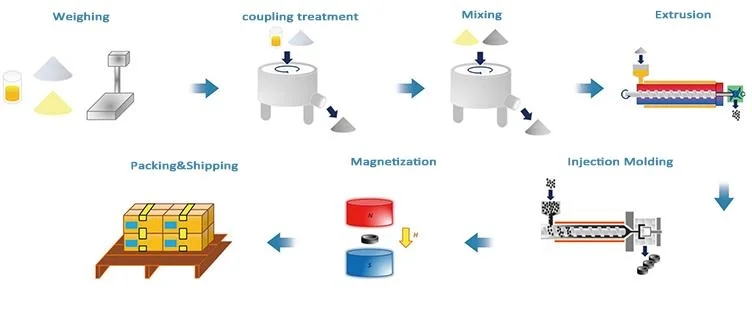

Production process:

Applications:

Fan Motors

Wiper Motors

EPS Motors

Starter Motors

Home appliance Motors

Industrial Motors

Motorcycle Motors

Other DC Motors

Product photography:

Advantages of Injection Molded Ferrite Magnets:

Complicated structures (with gears, gorges, teeth, etc.) can be realized;

High precision and tight mechanical tolerances;

Excellent tensile strength even with rapid rotation;

Potential for overmolding on different materials.

Producing department

Transportation

Why did you choose us?

1.We have ten years' experience in making magnets.

2.We are committed to the development and production of high-performance, high-precision and difficult products, in order to meet the requirements of motors, sensors and other products for magnets to work stably under complex conditions such as high temperature.

3.We work with a lot of companies like Schneider Electronics;Continental; Liebherr-CMCtec GmbH; DAC Electric B.V; Quadral GmbH & Co. KG;MEMSIC;TNE Korea Co., Ltd; HPV Technologies Inc; Dantax Radio AS; Audio Note UK LTD(in UK) ; Stage Accompany; Audeze;Jahwa Electronics etc.

4.Our certificate

FAQ

Q1. Why is the price of sample higher than that of batch?

A: For samples we don't have any profit. We only charge the cost of materials and labor. As a manufacturer, the more quantity produced, the lower the unit cost.

Q2. Why I should pay the Magnetic inspection fee? What is Magnetic inspection fee?

A: The freight is only paid by us to the transportation company for you, and the magnetic inspection fee is also a necessary cost generated in the process of transportation.

Freight companies require magnetic inspection reports when transporting magnets.Magnetic inspection report is a report provided by a professional magnetic inspection agency after testing that the magnet meets the transportation standards.

Q3.Why do I get magnets that break so easily?

A: Magnets are designed to be brittle and fragile. Remove the metal from the working area before using the magnet. Keep the distance between the magnets when using them at the same time. Even small magnets attracted to each other can break with such force.

Q4. Do you support exchange and return service?If I buy a magnet and I can't use it.

A: We do not support return or exchange service. As you know, the magnet is a custom product, which is completely customized according to your requirements. This product cannot be resold to others.

Q5. What will you do if there is a quality problem?

A: If you have any problem after receiving the magnet, please contact us immediately and shoot a video to us. We make records and take pictures of all the details when we ship. If it's our fault, we'll take the blame. If it happened in transit, we are not responsible for it.