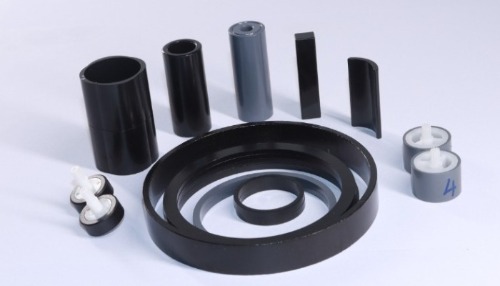

Customized Multi Poles Injection Molding Bonded Magnet Ring Compressed Neodymium Bonded Bldc Motor Magnet

Neodymium bonded magnets are typically made by mixing neodymium powder with a polymer binder such as epoxy or nylon. This mixture is then molded into the desired shape and cured to form a solid magnet. The binder helps hold the neodymium powder together and provides stability and durability to the magnet.

Brand:

KINGS MAGNETPayment:

T/T 100% IN ADVANCEProduct Origin:

Xiamen,CNShipping Port:

XIAMENColor:

BlackLead Time:

40 DAYSMany Years Experience Neodymium Magnet Manufacturer

100% Satisfaction Guaranteed On Quality

Samples and Trial Orders Are Most Welcome

Accept custom

Product base information:

In addition to the following magnetization directions, there are also radial magnetization of the inner diameter; radial magnetization of the outer diameter; axial one-sided magnetization and so on.

|

参数 Dimension |

尺寸范围 Size Range |

尺寸公差 Tolerance |

同轴度 Coaxiality |

同柱度 Cylindricity |

|

外径 OD |

20-75MM |

±0.05mm |

0.1mm |

0.04mm |

|

内径 ID |

15-68MM |

|||

|

壁厚 T |

2-7MM |

|||

|

高度 H |

5-50MM |

|||

|

镀层 Coating |

镍铜镍 ,环氧树脂 NiCuNi,Epoxy,etc. |

|||

|

应用 Application |

机器人 ,工业自动化生产线等 ,比如液晶面板生产线。 Robotics and industrial automatic production line,etc. |

|||

Bonded NdFeB Performance Table:

| Magnetic Characteristics and Physical Properties of Bonded Compression Moulding NdFeB | ||||||||||||

| 磁粉牌号 Grade | BN-2 | BN-4 | BN-6 | BN-8L | BN-8 | BN-8SR | BN-10 | BN-10H | BN-12 | BN-12L | BN-13L | |

| 剩磁Br | (mT) | 300-400 | 400-500 | 500-600 | 600-650 | 630-680 | 620-680 | 680-730 | 700-750 | 720-770 | 760-810 | 780-830 |

| Residual Induction | (KGs) |

(3.0-4.0) |

(4.0-5.0) | (5.0-6.0) | (6.0-6.5) | (6.3-6.8) | (6.2-6.8) | (6.8-7.3) | (7.0-7.5) | (7.2-7.7) | (7.6-8.1) | (7.8-8.3) |

| 矫顽力Hcb | (KA/m) | 240-320 | 240-320 | 320-400 | 360-440 | 400-480 | 400-480 | 400-480 | 440-520 | 440-520 | 400-480 | 400-480 |

| Coercive Force | (KOe) | (3.0-4.0) | (3.0-4.0) | (4.0-5.0) | (4.5-5.5) | (5.0-6.0) | (5.0-6.0) | (5.0-6.0) | (4.5-6.5) | (5.5-6.5) | (5.0-6.0) | (5.0-6.0) |

| 内禀矫顽力Hcj | (KA/m) | 480-640 | 560-720 | 560-720 | 640-800 | 640-800 | 880-1120 | 640-800 | 640-800 | 720-800 | 480-640 | 480-640 |

| Intrinsic Coercive Force | (KOe) | (6.0-8.0) | (7.0-9.0) | (7.0-9.0) | (8.0-10.0) | (8.0-10.0) | (11.0-14.0) | (8.0-10.0) | (8.0-10.0) | (9.0-10.0) | (6.0-8.0) | (6.0-8.0) |

| 最大磁能积(BH) max | (KJ/m3) | 24-32 | 32-44 | 52-60 | 60-68 | 68-76 | 68-76 | 76-84 | 80-88 | 88-96 | 88-96 | 88-104 |

| Max. Energy Product | (MGOe) | (3.0-4.0) | (4.0-5.5) | (6.5-7.5) | (7.5-8.5) | (8.5-9.5) | (8.5-9.5) | (9.5-10.5) | (10.0-11.0) | (11.0-12.0) | (11.0-12.0) | (11.0-13.0) |

| 可逆透磁率μr/Recoil Permeability |

(μ H/M) | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| 平均可逆温度系数 Tempetrature Coefficient |

(%/℃) | -0.11 | -0.11 | -0.11 | -0.11 | -0.11 | -0.10 | -0.10 | -0.10 | -0.10 | -0.12 | -0.12 |

| 居里温度Tc Curie Temperature |

(℃) | 300 | 300 | 300 | 300 | 350 | 350 | 350 | 350 | 350 | 320 | 320 |

| 最大工作温度 Max.Operating Temperature |

(℃) | 160 | 160 | 160 | 160 | 160 | 180 | 160 | 160 | 160 | 150 | 150 |

| 饱和磁化场 | (KA/m) | >1600 | >1600 | >1600 | >1600 | >1600 | >3000 | >1600 | >1600 | >1600 | >1600 | >1600 |

| Magnetizing Force | (KOe) | >20 | >20 | >20 | >20 | >20 | >25 | >20 | >20 | >20 | >20 | >20 |

| 密度ρ Density |

(g/cm3) | 4.5-5.0 | 5.0-5.5 | 5.5-6.0 | 5.8-6.0 | 5.8-6.1 | 5.8-6.1 | 5.8-6.1 | 6.0-6.3 | 6.0-6.3 | 6.0-6.3 | 6.1-6.4 |

| 硬度 Hardness |

HRB | 40-45 | 40-45 | 40-45 | 35-38 | 35-38 | 35-38 | 35-38 | 35-38 | 35-38 | 35-38 | 35-38 |

Advantage:

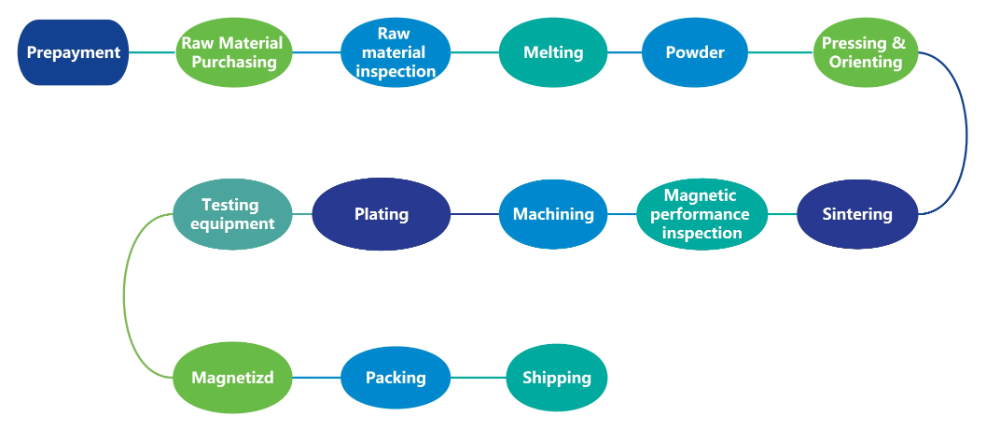

Production process:

Multi-pole magnets typically use dies and magnetizing tools.

So, if it is a new customized product, the turnaround time is about 40 days in total.

Inspection workshop:

Throughout the production process, we carry out at least 2 inspections, all in order to package the product in accordance with the customer's requirements.

Packaging + Shipping: